Often when people think of learning objectives for a course, they think, “what is the course going to teach?” That is the exact opposite of what a learning objective should be.

A learning objective should describe what the trainee is expected to learn or to be able to do as a result of the training.

As an employer or safety professional creating or selecting workplace and environmental health and safety courses, defining the learning objectives is critical to whether the course will be effective or not.

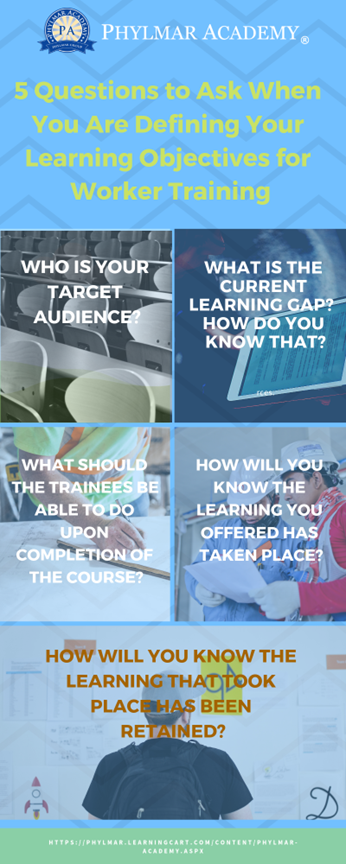

- Who is the target audience?

The first step is to define your target audience(s). It could be horizontal – workers at the same level possibly with different duties. It could be vertical – workers at different levels of responsibility, but in the same unit. It could be all new hires. It could be all workers who were trained the year before. Or any combination. But you must identify who needs to learn the material. And you need a deep dive into the demographics of the trainees in order to shape the training so that it is appropriate for them.

- Are there younger workers who would respond better to gamification?

- Are there older workers who need a larger font?

- What is the language of choice, education and/or comprehension level of the trainees?

- What are barriers, if any, that would prevent workers from being able to successfully complete the training?

- What is the current learning gap? How do you know that?

Let’s take Machine Guarding as a course topic for example. You have been through Step #1 and identified your target audience as the Sheet Metal Workers. Do sheet metal workers need to know how to protect themselves from the machines they use every day? Of course, they do. But do they (or some of them) already know what they need to know?

What kind of evidence would help you to know the answer? Look at your injury rates – are workers being injured by their machines? Look at industry safety records and reports – are machine injuries prevalent in your industry? Ask them – talk to your workers and ask them if they feel the need for more training in this area. Survey them – give them a short questionnaire and see if they give the right answers. Observe them – have a supervisor watch the workers for best practices, and also to make sure that machine guards are in working order.

These are just examples of different ways to determine if initial training, additional training or refresher training may be in order.

- What should the trainees be able to do upon completion of the course?

Once you have determined that there is a learning gap, you need to establish what you want the trainees to be able to do upon completing training. Start with 3-5 learning objectives. Trainees should be able to: recognize a broken machine guard, identify when a machine guard is being used properly or improperly, implement or design lock-out/tagout procedures, etc.

Notice that the learning objectives are written using active verbs. The trainees need to be able to do something. “Understand” is not an active word; “Learn” is not. Learning objectives are based on demonstrable knowledge or skills, not passive receipt of information.

Frame your learning objectives as, “by the end of this course, the trainee should be able to…” From there, you can use tools like Bloom’s Taxonomy to find the right verb from the basic level (Remembering) using words such as Recognize and Recall, up through the highest level (Creating) using such words as Generate, Plan, Produce. It may also be useful to enumerate or specify what is to be achieved – e.g., at the end of this course, you should be able to identify a broken machine guard on 4 types of machines, to list 3 steps to take when you encounter a broken machine guard, to compare the effectiveness of two types of machine guard.

You will want to tell them the learning objectives at the beginning of the course, and check whether the objectives have been achieved at the end of the course.

- How will you know the learning you offered has taken place?

There are many ways to determine if the learning you intended has taken place. You can:

- have knowledge checks and quizzes throughout the course

- have a final exam at the end of the course

- have them demonstrate a new hands-on skill in front of a supervisor

- ask them what they learned

- ask them to list 3-5 changes they will make in their workplace practices as a result of the course.

There are many other possibilities.

Determine an acceptable level for correct responses. 70% is a common benchmark. If they do not achieve your acceptable level, they need to retake the course.

- How will you know the learning that took place has been retained?

It is possible to get a perfect score immediately after an exam and then forget all the content immediately. To ensure that important information is retained and used, you can:

It is possible to get a perfect score immediately after an exam and then forget all the content immediately. To ensure that important information is retained and used, you can:

- Observe actual practice

- Check back and see if they actually put into practice the 3-5 changes they said they would make

- Review injury and illness reports to see if relevant statistics have changed

- Re-test (paper-and-pencil, computer-based, hands-on)

When to check on training retention? It’s up to you, but you should not let it go more than 90 days (3 months) before checking in with the trainees. You may even want to set up a quarterly schedule.

After one year, trainees can usually benefit from a refresher.

https://phylmar.learningcart.com/content/Phylmar-Academy.aspx

Web Design & Development by Endertech

Web Design & Development by Endertech